“The statement still holds true,” Zhang says. “Plastic is very important. People rely on it, and we can't be without it." But that also presents a challenge, he notes: "When [plastics] are at the end of their service, how can we deal with these materials?”

Zhang, along with a team of researchers, just published a paper in Nature Chemistry that attempts to answer that question.

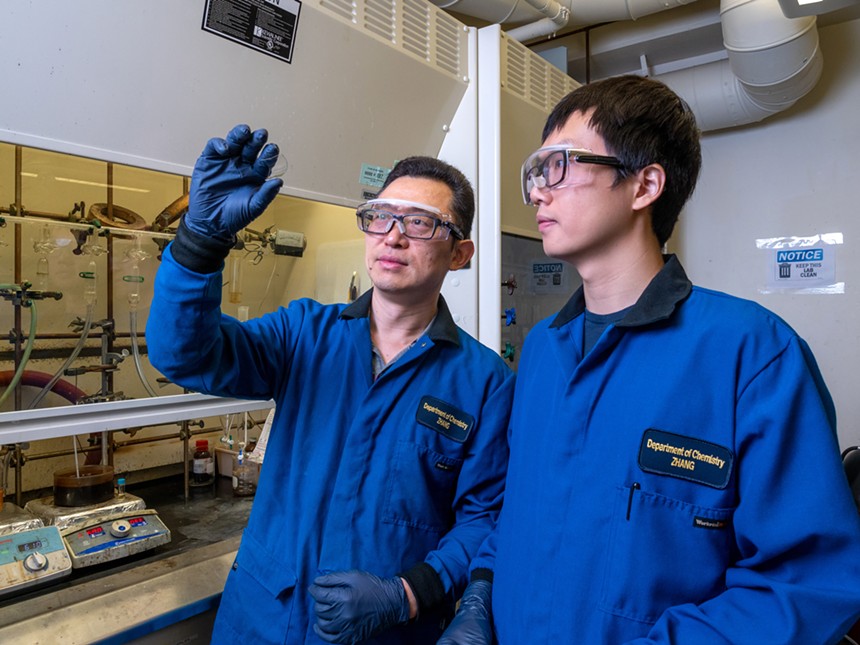

Zhang’s major area of study is reversible bond formation, and he’s been working on this type of chemistry since he came to the University of Colorado Boulder in 2008. He and his fellow scientists found a way to break plastics back down to their starting point, allowing them to be recycled in a closed loop. They discovered that by forming plastics with C–O bonds rather than C–N bonds, those bonds can be broken, returning the polymers that form plastic back to monomers. Those monomers can then be repurposed into new polymers used to form plastic products without the need to burn more petroleum or use the toxic, expensive starting materials required to create C–N bonds.

A circular economy for plastic is possible, thanks to new research.

Patrick Campbell/University of Colorado

Enabling the recycling and reuse of polymers will help prevent plastic waste. Zhang says the goal of the research is to make plastics that are similar to trees, flowers and animals: At the end of their life span, they’re recycled to make new life. Once plastic has served its purpose, C–O bonds can be broken down to kickstart the creation of new plastic.

According to Zhang, this method for making plastic is less expensive and less toxic than the method that’s commonly used, and it works in reverse: Even polymers that were formed with the traditional method can be broken down and recycled using the C–O bond method that the CU researchers discovered and tested.

Along with helping eliminate visible plastic waste, such as debris on highways and in landfills, this recycling method can also cut down on microplastics, famous for appearing in garbage patches in the ocean that some people call trash islands. They exist because until this research, plastic was not completely degradable. A plastic bag can be broken into pieces small enough to infiltrate cell membranes, but those pieces are still not monomers and can’t be collected or repurposed. Instead, they enter the water supply or the air, and then often the human body.

Wei Zhang (left) in the Zhang Lab at CU Boulder with grad assistant Zepeng.

Patrick Campbell/University of Colorado

In the meantime, this research will allow plastics to be fully broken down and turned into usable material rather than tiny, unrecyclable plastics. Zhang says that PCN, the type of polymer they specifically studied, has high thermal stability and is flame-retardant. It can be used to form the plastic parts of airplanes and cars as well as everyday items.

“That's why we believe this technology, hopefully in the near future, can really help make the manufacturing of this type of resin on an even larger scale more readily accessible,” Zhang adds.

Before publishing the paper, the researchers obtained the patent for the technology. Zhang says he’s already had venture capitalists reach out, asking if the process can be used outside the lab. He’s not quite ready for that step, and says he wants to be sure that the rest of the team, and the university, play a part in the eventual licensing and application of the product.

Until then, he hopes people will take care when using plastic in their daily lives.

“Do I really need one extra plastic bag? Do I really need an extra plastic bottle?" he asks. "I'm not saying just don't use it. That's impossible. But it's just to give you another thought.”