It’s been 54 years since Neil Armstrong left his footprints on the moon’s surface. While Apollo 11’s round-trip mission took eight days, astronauts now spend an average of six months living on the International Space Station (ISS), making it more important than ever to have access to nutritious and delicious meals in a gravity-free environment.

In the early days of space flight, astronauts either tried not to eat or would endure pastes made from meat and vegetables that could be squeezed out of tubes. Today they have access to a variety of thermostabilized or freeze-dried foods that can be rehydrated and heated using microwaves or convection ovens.

The meals astronauts eat on the ISS every day are similar to the MREs (Meals Ready to Eat) used in the armed forces or the trail-friendly food available at outdoor stores like REI. But as NASA sets its sights on crewed missions to Mars and beyond, it’s planning for multi-year journeys that have higher demands for nutritious and self-sustaining food systems. Almost as important as the dietary needs of the travelers, food offers psychological support: A home-cooked meal boosts morale, decreases homesickness and is an act of community.

But actual cooking is pretty difficult in space. The first, and seemingly last, experiment took place in December 2019, when ISS astronauts tested baking a chocolate-chip cookie in a custom-designed oven for space. It took 130 minutes to bake the DoubleTree cookies. Unfortunately, the astronauts weren’t allowed to eat the treats, which were sent back to NASA for testing.

One Boulder scientist is working to change the game when it comes to food in space.

Jim Sears was a senior in high school when he watched Armstong take his historic step onto the moon’s surface, piquing his interest in the cosmos. From 1980 to 1990, he worked as a systems engineer at Ball Aerospace in Boulder, where he learned about the unique challenges and logistics of operating in space.

After his time at Ball, Sears bounced between entrepreneurial ventures while consulting with various aerospace companies through his business, Ascent Technology. During one of those consulting gigs, “I found there was a problem in doing mining operations on the moon, and that’s how to heat things up very hot,” Sears explains. “The problem is twofold: one, to get something extremely hot, you need a heating element that’s much hotter, because we normally heat things by radiation. And the other problem is that when there’s low gravity or zero gravity, it’s very hard to heat things by convection.” (Convection heating transfers heat through air, so in space, where there’s little air, it’s pretty inefficient.)

Sears began to dream of a spinning cylinder that would create its own artificial gravity through centrifugal force. As the cylinder spins, the material would be pushed against the walls and could be heated through conduction, which occurs through physical contact with heating elements.

A true engineer with the obsession of an inventor and the tenaciousness of a tinkerer, Sears had already converted his garage into a full workshop with a milling machine, lathe, bandsaw and microscopes. Located on a quiet residential cul-de-sac in Boulder, it's stuffed to the brim with hardware, electrical components and parts that he used to begin prototyping his idea.

Still focused on mining, he started with attempting to vaporize zinc, which ended in a mess. "I was like, 'This is ridiculous. ... Let me change my goals. I’m just going to try to boil water and start simple,'" Sears recalls. "So I took a tuna can, put in water, used a drill to spin it, and I used a propane torch and heated up the spinning outside of the tuna can. And then it started boiling! And so I started doing more elaborate versions of that.”

This was during the pandemic in 2020, and Sears was already semi-retired, so he had plenty of time to perfect his invention. He started adding heating elements, experimenting with stainless-steel cylinders, putting on a transparent lid and tacking on heat sensors. “It was like taking a deep intellectual dive because I was so curious," he says. "No one had ever done this...so I was really curious how it would turn out."

He demoed his invention over Zoom for a close friend who, disappointingly, seemed unimpressed by Sears's ability to boil water in a spinning can. That inspired him to use the technology on food, starting with Amy’s brand split pea soup. If he could dehydrate the soup without burning or boiling it, it would prove that his device could precisely control temperature and power. Twelve minutes later, he was chowing down on some split pea leather. “That’s when I realized I could probably use this for cooking,” Sears says.

He named his invention the SATED oven, which stands for "safe appliance, tidy, efficient and delicious." On Christmas Day 2020, he invited his family to the garage to taste some cylindrical pancakes and “inside-out” pineapple cake. It wasn’t entirely edible — Sears had yet to dial in the recipes — but it was a milestone nonetheless: He had proven that his SATED oven could cook.

Next, he set about making his invention space-compliant. The most important change was adjusting his design to work with positive temperature coefficient (PTC) heaters, which are already used in the aerospace, automotive, health-care and outdoor recreation industries, where traditional heating can lead to dangerous conditions. PTC heaters are made of advanced ceramic materials, which means that they plateau at a maximum temperature because of intrinsic chemical characteristics. So even if there’s an electrical malfunction or surge, they will never surpass that maximum temperature.

“I picked crystals that have a [max] temperature of 220 degrees Celsius because at 220 Celsius, you can get things really hot, but not so hot that they can actually burst into flame,” Sears explains. You can also pick up a PTC heater on Amazon for under $20.

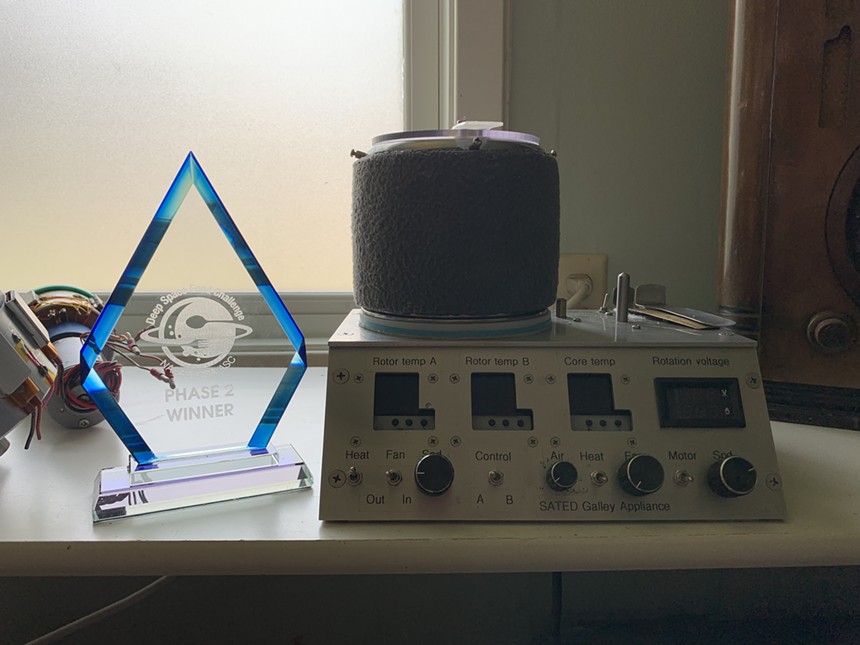

In addition to new heaters, Sears experimented with replacing rotors, putting in more powerful motors and using an inserted heating element. In the corner of his garage is a shelf where all the iterations of the SATED oven are neatly lined up in chronological order, left to right. It begins with the humble tuna can and ends with a fully functional oven replete with PTC heaters and sensors mounted on a base with an analog control board. Tucked behind the machine is a small glass plaque engraved with the words “NASA & CSA/ASC Deep Space Food Challenge: Phase 2 Winner.”

The Deep Space Food Challenge is one of NASA’s Centennial Challenges, which offer prizes to the public for tackling specific technical challenges faced by NASA and the broader aerospace community. The DSFC was started in 2018 to specifically address food-system technology for deep space travel and planetary habitation.

“So right now, the food system is based on packaged food on the ISS, but they do have to resupply — they take fresh foods sometimes as well as treats to replenish the menu and give it some variety,” explains DSFC manager Angela Herblet. “But when you think about deep space, we’re not going to be able to do that. So it has to be many things. It can be pre-packaged food, it can be fresh food, 3D-printed food, mushroom protein. ... We really wanted to reach out to the public and capture what’s going on now in food that could potentially contribute to this future food system.”

For the three-phase challenge, the process and the food produced by the inventions have to be safe to operate as well as consume; reliable and able to operate for multiple years with relatively low maintenance; and resource-efficient. One requirement that is notably lacking is the ability for the inventions to operate in low or zero gravity; Herblet says that NASA thought that would be too difficult of a requirement for non-NASA engineers to meet.

Phase I launched in January 2021, but Sears initially dismissed the challenge. "From the way it was being promoted, I thought, ‘This is just something for students,’” he says. However, it did motivate him to formalize his designs and file for patents in case the increased spotlight led to competition. “The next thing I discovered was that these companies that actually joined the competition won money. And, whoa, this actually was an opportunity to get money and attention.”

When Phase II launched, in January 2022, Sears filled out NASA’s extensive application, and his daughter found a professional videographer to make the required video showing how the machine works.

Almost a year later, Sears was announced as one of eleven finalists — and is the only one focused on cooking food in space. Many of the other inventions are aimed at growing and producing produce, mushrooms and insects. One of the finalists, Brooklyn-based Air Company, developed a carbon dioxide capture system to produce alcohol, albeit to feed yeast, not for astronaut consumption.

In March, two NASA judges visited Sears's garage for an on-site demonstration, which he says was a rousing success. They stayed for four and a half hours and made eight different meals. Sears originally made them a pepperoni and cheese pizza, “and then one of the judges, she took over and made everything else from then on," he says. "And so they had the thrill of discovery themselves...and that was exactly what I was trying to create. I’m trying to create a machine that allows you to have creative freedom."

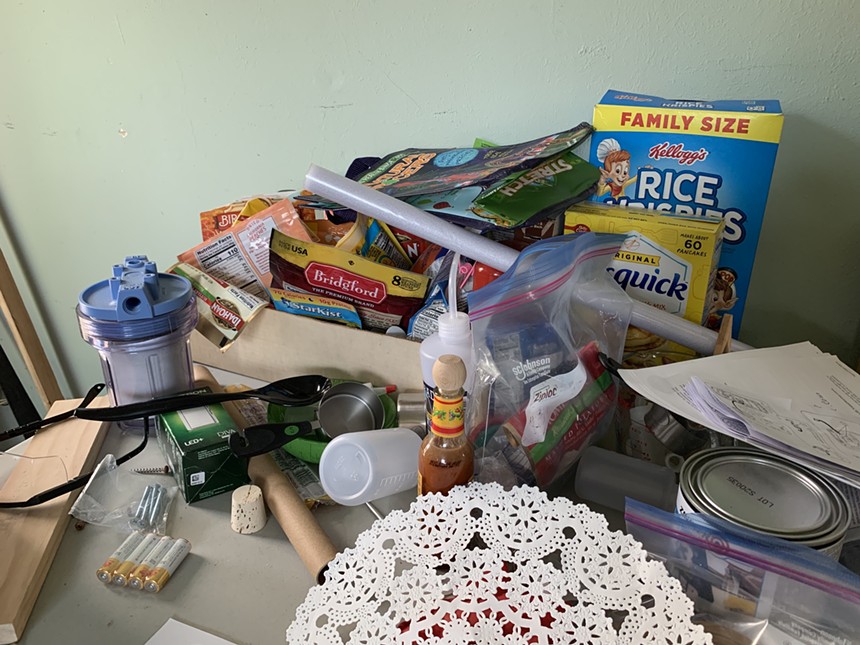

In his lab, Sears has an entire cardboard box of ingredients including Slim Jims, dehydrated mashed potatoes, egg crystals, boxed cake mix, dried fruits and vegetables. For hours, the judges mixed and matched different ingredients to make potatoes, omelets and more pizzas. “The totally delightful thing is I had actual experts in my lab [for the first time],” Sears says.

After NASA's visit, Sears continued to refine his design and brought on someone to help. George Abuhamad is a freelance mechanical engineer who specializes in 3D design, modeling and printing. Together, he and Sears built the current iteration of the SATED oven, which takes up less volume than a cubic foot and weighs roughly twelve pounds. It has three main controls for heating, rotation speed and the fan.

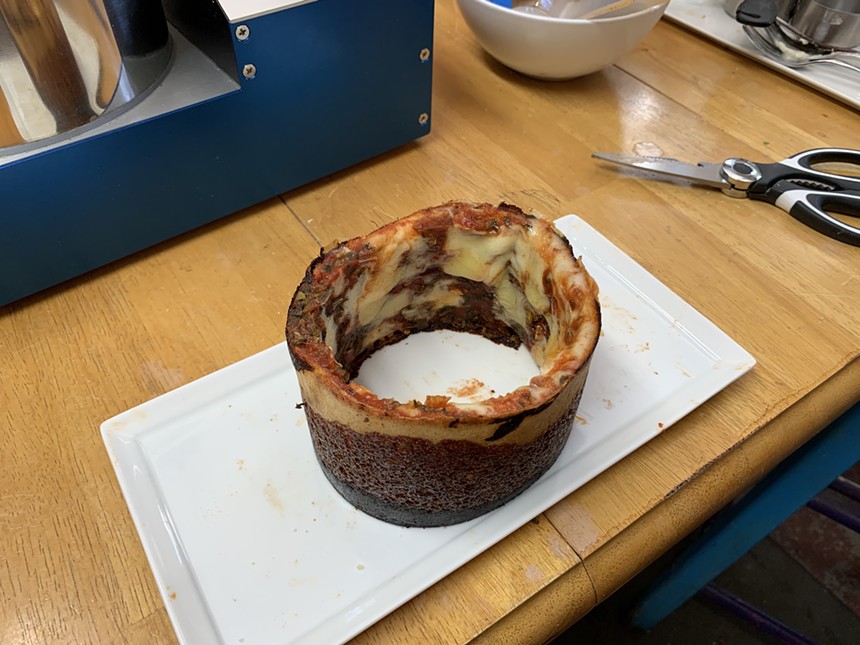

We recently visited Sears's garage, where he and Abuhamad made a pizza using Bisquick, Trader Joe’s Fat-Free Pizza Sauce and mozzarella string cheese. Abuhamad set the cylinder to 185 degrees Celsius and 530 RPM before pouring in the prepared Bisquick mixture. “Oh, shoot, I forgot to add the cheese,” he said. Sears shrugged and then offered an idea: “Let’s at least turn it on its side.”

He was trying to counteract the effects of gravity so the Bisquick mixture would evenly coat the sides of the cylinder versus forming more of a cone shape. We watched the mixture spin round and round for the next five minutes. After opening the lid, Abuhamad poked the dough with a gloved finger and announced that it was cooked. He poured the pizza sauce in and, after a few minutes, he used scissors to cut small pieces of mozzarella string cheese into the cylinder, where the centrifugal force pushed it to the sides.

In another ten minutes, the pizza was cooked, and Abuhamad flicked on the fan. Because astronauts are busy folks, "we have to heat as well as cool so the food comes out of the oven ready to eat,” explains Sears.

Once ready, Abuhamad used two 3D-printed holders to lift the cylindrical pizza and set it on a cutting board. It was an odd-looking pizza, for sure — five inches in diameter and almost three inches tall — but once Abuhamad cut down the side, it unfurled into a long, skinny flatbread pizza.

My dining partner described the flavor as “middle-school cafeteria pizza, but in the best way.” The crust was half an inch thick, fluffy and evenly browned, the sauce was standard, and because the cheese hadn’t had direct heat contact, it was melted but not browned. While the result was pretty average on Earth, it's not hard to imagine how it could be nirvana to astronauts who have not had a taste of home in weeks, months or possibly years.

After the first test, Sears wanted to retry the pizza, adding the cheese first so it would brown on the crust. This time, Abuhamad mixed spoonfuls of dehydrated bell peppers, spinach, broccoli, jalapeños and onions into the sauce before adding it to the oven. The tweaks resulted in a pie that was actually delicious. Thanks to the cheesy crust, the pizza had a crunch while maintaining its fluffy structure, and the sauce was spicy and flavorful.

Sears and Abuhamad have had a lot of practice perfecting the pizza recipe. As Phase II finalists, they participated in NASA’s Innovation Showcase in May at the Brooklyn Navy Yard, where they served an estimated ten pizzas a day to participants and attendees.

The showcase aligned with New York’s Design Week and took place at Smart Design’s studio. "Thirty minutes before they announced the winners, one of the NASA guys came over and told us to stand by a table with our oven and that someone’s going to come and interview us. And I thought, okay, they probably don’t want to interview someone who’s really sad.” He was right. The SATED oven was one of eight Phase II winners; each received $150,000 in prize money and moved on to Phase III.

The third and final phase of the Deep Space Food Challenge will “continue testing the feasibility of the system and repeatability of it. So [Phase] I was, ‘Show me what you’re thinking'; Phase II was, 'Show me how it worked'; Phase III pushes that development even further, and if it can work multiple times,” explains Herblet.

The Phase III requirements are set to be released “in the next few weeks,” according to Herblet, but NASA was able to provide some details about the judging. Each participant will be taken to a designated facility where they will train a qualified crew on how to work their technology. Then the crew will test it under analog conditions repeatedly and provide feedback to the judges. There will also be traditional lab analysis of the food as well as potential “professional sensory testing,” Herblet says. Winners of Phase III will be announced in 2024 and will split a prize pot of $1.5 million.

Winning the Deep Space Food Challenge, though, does not come with any commitment on NASA’s part to extend a contract or put the technology in space. "In all Centennial Challenges, the competitors keep all their intellectual property; NASA makes no claim to it," explains Jonathan Deal, public affairs officer for NASA's Marshall Space Flight Center. "Because of this, NASA does not offer contracts as part of the prize purse."

The only expectation is that competitors will agree to talk to NASA if there's interest in developing/using their technology. “But what we try to do through the competition is really build it into a platform for exposure for teams,” explains Herblet. “We’re trying to create this platform where we’re giving [the participants] a place to talk tech, demonstrate their technologies, to show it, to network it, to make those connections, allow the technologies then to live on outside of the competition.” To go from proof of concept to space-worthy technology requires jumping over numerous bureaucratic and technical hurdles, so Sears has partnered with BioServe Space Technologies, a University of Colorado Boulder research center and one of the only nonprofits in the country designated as an accepted NASA Implementation Partner.

BioServe maintains the staff and facilities on its campus to engineer and manufacture technology that will meet NASA’s stringent safety standards. “It sounds very boring, but like wire-size analysis. We have to make sure they’re using all the correct wiring sizes and the correct type of wire,” explains Stefanie Countryman, director of BioServe. “NASA doesn’t want any type of electromagnetic interference to occur, because there’s lots of powered systems on-board the station that are required to keep the crew alive."

There are hundreds of little details to consider when engineering for space. You can’t have red buttons or lights, for example, because red on the station signifies an emergency or disaster. “We flew a power module for a piece of hardware a few years back, and it had three different lights on it,” remembers Countryman. “We probably had a two-hour-long conversation on what colors we could make it and what colors we should make it and what the crew would think and whether or not NASA would approve them.”

Some of the most significant engineering is related to adapting the technology to low and zero gravity. Sears is hoping to get a head start on that research by testing the SATED oven on parabolic flights, which cost $55,000 and have thirty instances of zero gravity that last seventeen seconds each. He was able to go on one in 2022 with the SATED oven through a grant program, and is waiting to hear back on another proposal to test again on an upcoming flight.

After the SATED oven has been made space-compliant, it will most likely make its maiden journey to the ISS either through NASA or the ISS National Laboratory. (In 2005, Congress designated 41 percent of the ISS open to research from small companies, Fortune 500 companies, research institutions and anyone else interested in experimenting in a microgravity environment.)

If the project is approved, Countryman estimates it would be 18 to 24 months before the SATED oven could make it to the ISS. That time includes engineering, manufacturing, certification and waiting in the queue for a mission with room for the invention to be tested in space.

She adds that it would likely be another one to two years before Johnson Space Center Food Lab, the ultimate gatekeepers to what astronauts do and don't eat, gives approval for space crews to actually put the oven in regular use to cook meals.

There’s also the possibility of SATED making its way to space on a commercial operation such as Blue Origin’s planned Orbital Reef, Vast or Axiom Stations; Voyager’s Starlab; or SpaceX’s Starship, as these have different testing and compliance standards.

Despite the long road ahead, Sears remains optimistic. "It's just a matter of when," he concludes. "When people in space get hungry enough to demand it, or people on Earth have the culinary compassion to give it to them. Regardless of when or where SATED gets deployed, this project has been, and remains, the most exciting and meaningful technical adventure I’ve ever been on. I’ve got huge amounts of gratitude that I happened to be the lucky one to discover and be able to take care of SATED.”

[

{

"name": "Air - MediumRectangle - Inline Content - Mobile Display Size",

"component": "12017618",

"insertPoint": "2",

"requiredCountToDisplay": "2",

"watchElement": ".fdn-content-body",

"astAdList": [

{

"adType": "rectangle",

"displayTargets": "mobile"

}

]

},{

"name": "Editor Picks",

"component": "17242653",

"insertPoint": "4",

"requiredCountToDisplay": "1",

"watchElement": ".fdn-content-body",

"astAdList": [

{

"adType": "rectangle",

"displayTargets": "desktop|tablet"

},{

"adType": "rectangle",

"displayTargets": "desktop|tablet|mobile"

}

]

},{

"name": "Inline Links",

"component": "18838239",

"insertPoint": "8th",

"startingPoint": 8,

"requiredCountToDisplay": "7",

"maxInsertions": 25

},{

"name": "Air - MediumRectangle - Combo - Inline Content",

"component": "17261320",

"insertPoint": "8th",

"startingPoint": 8,

"requiredCountToDisplay": "7",

"maxInsertions": 25,

"watchElement": ".fdn-content-body",

"astAdList": [

{

"adType": "rectangle",

"displayTargets": "desktop|tablet"

},{

"adType": "rectangle",

"displayTargets": "desktop|tablet|mobile"

}

]

},{

"name": "Inline Links",

"component": "18838239",

"insertPoint": "8th",

"startingPoint": 12,

"requiredCountToDisplay": "11",

"maxInsertions": 25

},{

"name": "Air - Leaderboard Tower - Combo - Inline Content",

"component": "17261321",

"insertPoint": "8th",

"startingPoint": 12,

"requiredCountToDisplay": "11",

"maxInsertions": 25,

"watchElement": ".fdn-content-body",

"astAdList": [

{

"adType": "leaderboardInlineContent",

"displayTargets": "desktop|tablet"

},{

"adType": "tower",

"displayTargets": "mobile"

}

]

}

]